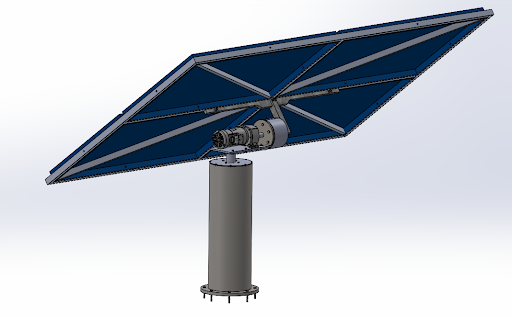

Solar panel assembly

For a design and manufacturing class at Case Western Reserve University, I acted in the capacity of project manager for the task of designing a dual axis solar panel assembly. This would hold four 250W solar panels while having rotational capabilities on two axes which allows it to track the suns position in the sky throughout the day, correlating to a 25% increase in efficiency. The specifications were that the assembly should function in a remote area with maintenance only being required once per year and should be in service for at least 7 years. As project manager I gained experience with planning out GANNT charts and task lists, as well as contributing with my design knowledge.

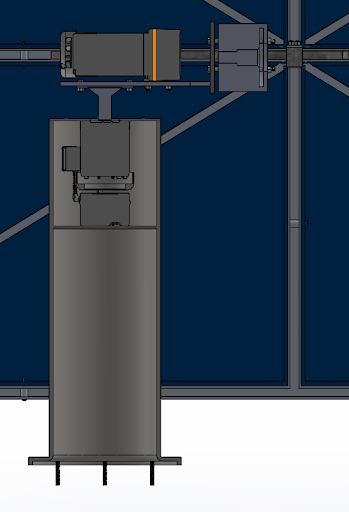

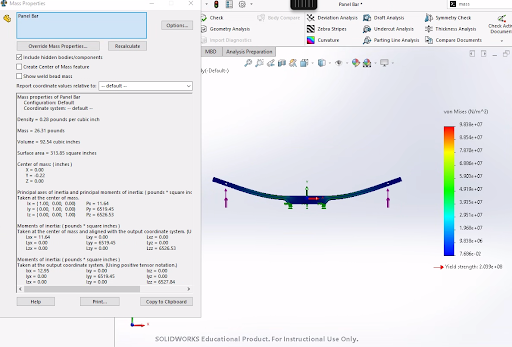

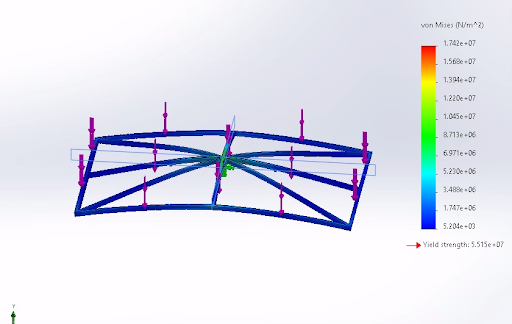

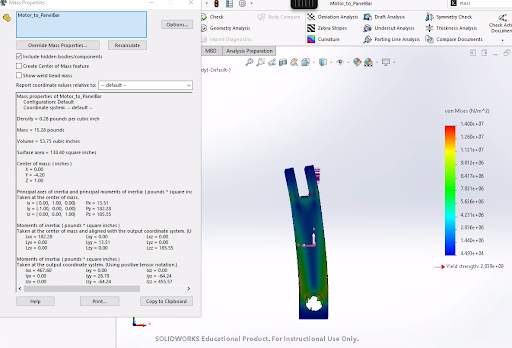

For our design I did calculations of structural analysis, specifically on the rivet strength needed (rivets used to ensure even stress distribution with shear stress, unlike some bolts with tolerances to drill holes). Additionally torque was analyzed for speccing the motors based on assembly weight and distance from the axes of the motors. Finally I ran Finite Element Analysis on all parts to ensure that parts meet a reasonable factor of safety.

Full Isometric view of Solar Panel Assembly

Cross section view of two motors powering rotation

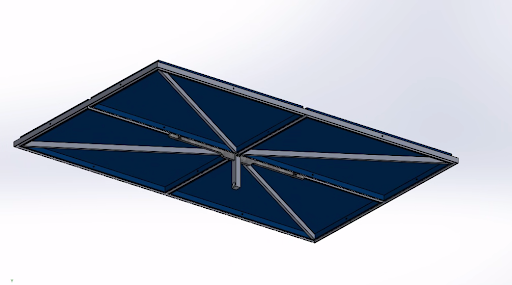

Isometric view of 4 solar panels attached to frame which is connected to two bars that attach to the motor

FEA analysis on bar that connects directly to the frame

FEA analysis on the frame holding the solar panels; Held in place by bolts along the frame which generated our load points

FEA analysis of the bar that connects the motor to the longer bar

Failure Mode and Effects Analysis for the assembly to assure that there will be seven years of service